Swing Beam Shearing Machine

- The Hydraulic Swing Beam Shearing Machine boasts versatile capabilities.

- Ensuring precise and efficient cutting across a diverse range of materials and thicknesses.

- making it an ideal choice for sheet metal fabrication and metalworking applications.

Guillotine Shearing Machine

The Hydraulic Guillotine Shearing Machine excels in heavy-duty cutting tasks, delivering clean and straight edges with its robust design and powerful hydraulic system, making it an ideal solution for industries requiring high-volume production of large metal components.

Main Configuration

Estun E21 NC Controller

High-Definition Hydraulic Display

Control for Common Motors and Frequency Converters

X-Axis Intelligent Positioning

Multi-Step Programming with 40 Programs

Built-In Time Relay Function

One-Button Function Switching

Unilateral Positioning Function

Key Backup and Parameter Restoration

Chinese and English Interface

Metric System Compatibility

The Back of Hydraulic Shearing Machine

Sturdy Backgauge for Enhanced Durability: The heavy-duty backgauge design ensures collision resistance and minimizes the risk of deformation, contributing to the machine’s long-term durability.

Efficient Material Handling with Convenient Backgauge Rack: A user-friendly backgauge rack simplifies material retrieval, streamlining the cutting process for enhanced efficiency.

Versatility in Cutting with Adjustable Backstop: Both manual and automatic backstop lifting functions accommodate varied cutting needs, providing operators with flexibility for handling longer materials.

Main Motor

High-Capacity Main Motor Options: Our high-capacity main motor is customizable to accommodate globally acclaimed brands such as Siemens or well-known Chinese brands like Wannan, providing flexibility based on your preferences and requirements.

Voltage Customization for Specific Needs: To meet specific operational needs, we offer voltage customization with options including 3-phase / 220 V / 60 Hz, 3-phase / 380 V / 60 Hz, 3-phase / 415 V / 60 Hz, and other configurations tailored to your specific requirements.

Rexroth hydraulic system

Utilization of Globally Recognized Rexroth Hydraulic Valve Block:

The incorporation of the Rexroth hydraulic valve block ensures optimal hydraulic functionality, utilizing a globally recognized and reliable component.

Oil Leakage and Valve Jamming Prevention:

The machine features an oil pressure overload protection system, minimizing the occurrence of oil leakage and valve jamming. This enhances the reliability and longevity of the equipment.

Real-time Oil Pressure Monitoring for Uninterrupted Operations:

To ensure uninterrupted oil circuit operations and consistent equipment performance, real-time oil pressure monitoring is offered. This feature allows for proactive adjustments and maintenance, contributing to the machine’s efficiency.

Efficient Workbench

Reduced Friction for Smooth Plate Surface: The ball-type front support minimizes friction between the plate and the table, ensuring a seamlessly smooth plate surface.

Enhanced Cutting Efficiency through Convenient and Fast Feeding: With a redesigned feeding system, our machine facilitates more convenient and faster material feeding, resulting in significantly improved cutting efficiency.

Safety and Customization in Feeding Height: Our machine adheres to international safety standards with a carefully designed feed port. It offers a minimum feeding height equal to the sheet thickness and a maximum feeding height equal to the sheet thickness plus 20-25mm. Adjustable height screws enable easy customization for feeding height, while a front fence and side guardrail ensure operator safety during operation.

Machine Bed

- Integral processing ensures bed accuracy.

- Heat treatment in a tempering furnace eliminates internal stress during welding and prevents the bed from deforming easily.

Ball Screw & Liner Guide Backgauge

- Enhanced Precision:Linear guide rails contribute to heightened precision in machine movement, ensuring accurate positioning and minimizing errors.

- Smooth and Consistent Movement:The linear guide rail enables smooth and consistent backgauge movement, ensuring uniform shearing and reducing the risk of irregularities.

- Reduced Friction and Wear:Advanced linear guide technology minimizes friction, extending equipment lifespan and maintaining backgauge precision over time.

Lubrication Device

- Enhanced Convenience and Speed: Our product ensures efficient and productive operations by offering enhanced convenience and speed.

- Two Models for Operational Flexibility: Available in automatic and manual models, our product caters to diverse operational preferences, providing flexibility for users.

- Effortless Model Selection: Users can effortlessly choose between automatic and manual models, tailoring the machine’s operation to align with their specific needs.

- Tailored to User Preferences: The flexibility in model options allows users to customize the product according to their preferences, optimizing the overall user experience and satisfaction.

10% off your first purchase.

Leave your email or phone number and we will back to you within 24 hours.

Pneumatic Rear Support

Stability in Material Support:

- The Pneumatic Rear Support ensures stable material support, preventing sagging or deformation during shearing.

Efficient Handling of Large Sheets:

- Particularly beneficial for large sheets, the pneumatic rear support maintains material alignment, enhancing efficiency in shearing.

Operator Convenience and Safety:

- Simplifying material handling, the pneumatic rear support reduces physical effort for operators and enhances safety during the shearing process.

Hydraulic Oil Cooling Device

1. Efficient Temperature Control: Maintaining Optimal Operating Conditions

2. Prolonged Equipment Lifespan: Preventing Overheating for Longevity

3. Enhanced Hydraulic System Performance: Consistent Operation in Diverse Applications

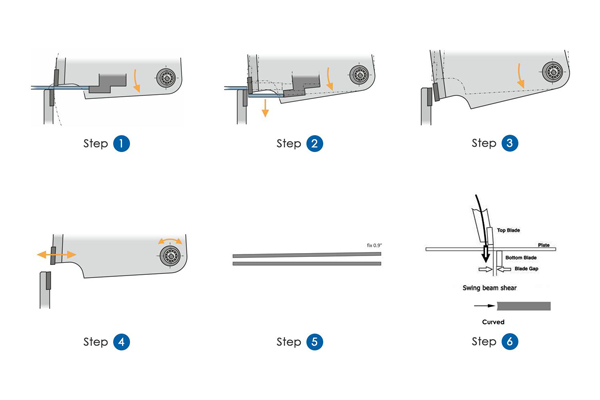

Principle of swing beam shearing machine

Precise Cutting Motion:

- The upper blade initiates the cut by pivoting above the lower edge on the swing beam.

Smooth Blade Separation:

- After cutting, the upper blade smoothly moves away from the lower blade, ensuring a friction-free separation.

Adjustable Clearance for Versatility:

- Easily customize blade clearance with the cutting gap eccentric, accommodating various material thicknesses while maintaining precision.

Efficient Riding Shear Design:

- The design’s low rake angle enables an efficient riding shear approach, ensuring effectiveness across different material thicknesses.

Processing Equipment

We pay attention to every detail of the machine and are committed to creating the perfect hydraulic swing shearing machine for our customers.

More Pictures

- Cutting-Edge Design: Swing Beam Shears feature advanced technology and a user-friendly interface, ensuring efficiency.

- Precision and Efficiency: By minimizing the cutting angle, we achieve straight precision and reduce twist tolerance for accurate cuts.

- Hydraulic Excellence: Our Hydraulic Shearing Machine excels with high-standard safety features, enhancing capabilities and adding value to your operations.