Vertical V-groove

Our vertical grooving machine delivers precise and efficient grooves in sheet metal. It’s ideal for working with stainless steel, aluminum, and other metals, ensuring accurate and clean grooves for various industries like metal fabrication and architecture. Easy to use, it provides consistent, high-quality results.

Horizontal V-groove

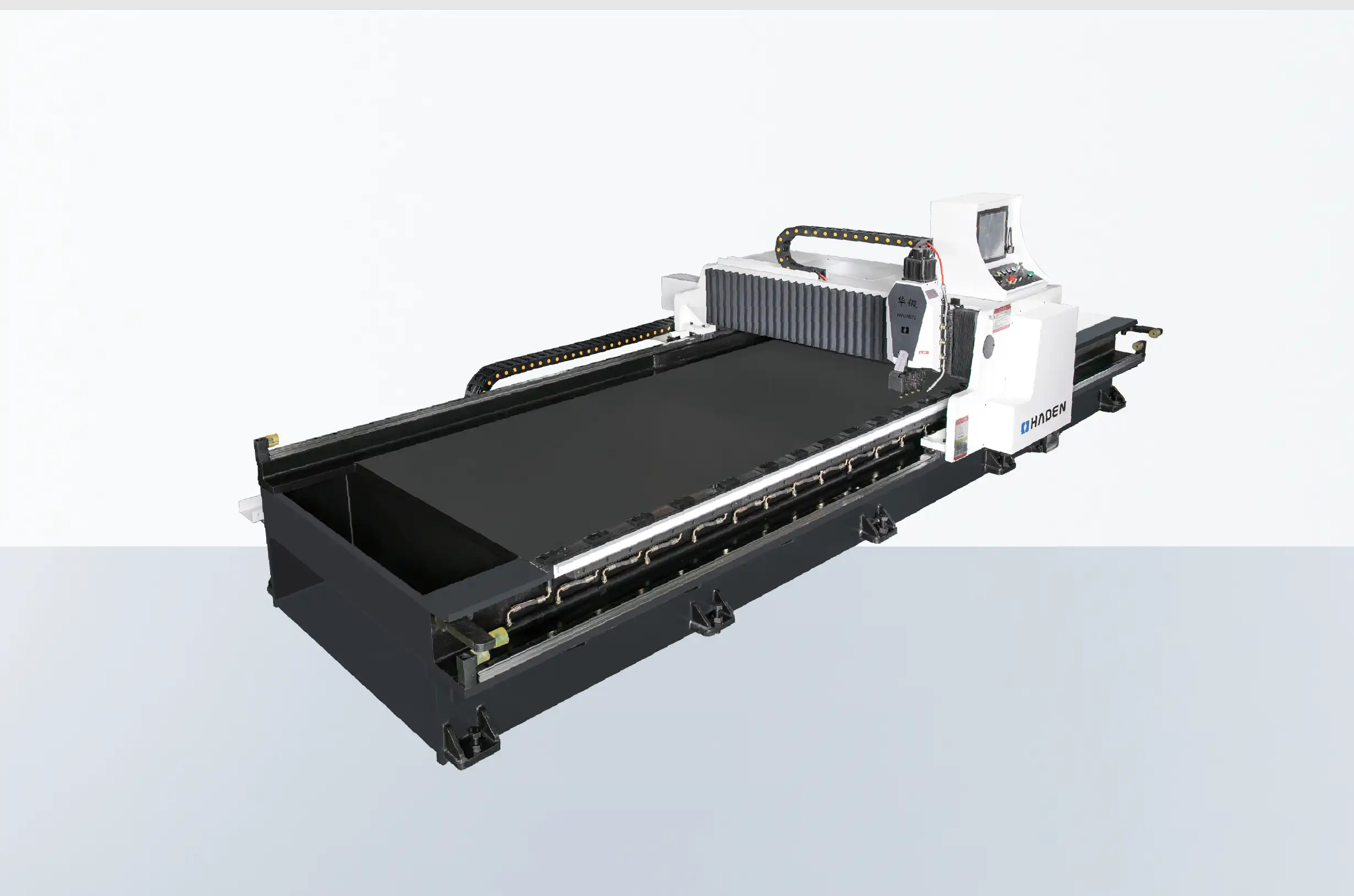

Designed for accurate horizontal grooves, our machine is perfect for large-scale metalworking projects. It works with materials such as aluminum and stainless steel, delivering smooth, precise cuts. This machine enhances productivity while maintaining high-quality results across various applications.

Vertical vs. Horizontal V Groove Machines: Which One is Right for Your Business?

Overview: Understanding V Groove Machines

- Vertical vs. Horizontal Structures:

Vertical machines use an upright design, while horizontal machines lay flat, each suited for different materials and operational needs.

Structural Differences

- Vertical Machines:

Designed for tall or oversized sheets. Ideal for processing large panels in limited floor space. - Horizontal Machines:

Better for consistent, high-precision grooving on flat materials. Typically more stable during operation.

Applications

- Vertical V Groove Machines:

Best for tall, narrow panels or limited workspace environments. Popular in construction and architectural cladding. - Horizontal V Groove Machines:

Ideal for precision applications like cabinet-making, where steady, flat materials are key.

Functionality & Performance

- Vertical Machines:

Suitable for large workpieces but may have slower throughput due to manual adjustments. - Horizontal Machines:

Known for precision and efficiency, especially for industries needing repeatable grooves on flat surfaces.

Pricing Considerations

- Vertical Machines:

Generally more affordable due to simpler designs but may incur higher labor costs due to manual handling. - Horizontal Machines:

Higher initial investment but lower operational costs over time with faster, automated features.

Buyer Recommendations

- For Space-Saving Needs:

Choose a vertical machine for tight floor spaces. - For Precision:

Horizontal machines deliver better precision and throughput for high-volume projects.

Conclusion: Making the Right Choice

- For Large Panels or Space-Limited Operations:

Opt for vertical machines. - For High-Precision, Repetitive Jobs:

Horizontal machines are more suitable and may offer better long-term ROI.

Buy Local

Premium Service from Local Experts

+ 10%~30%

$

Service Fee

-

Import

-

Installation

-

Training

Find Local Agents

Reliable Service You Can Trust

Import Directly

Factory-Direct Pricing for Experts

EXW Price

$

No Extra Fees

-

3-Year Guarantee

-

Online Support

-

Custom Solutions

Obtain Your Quote

Get detailed solutions

Save Big

Partner Up

Join Our Agent Network

- 10%

$

Special Order

-

Client Inquiries Provided

-

On-Site Technical Training

-

Flexible Payment Terms

Boost Your Sales

Get a Dealer Quote

Structure & Frame

- The machine features a robust frame design, with a 60mm low-alloy, high-strength steel worktable and a Q345 steel plate frame.

- This combination delivers outstanding rigidity and durability, ensuring a long-lasting and solid construction.

CNC Controller

- Equipped with a Taiwan CNC system, the machine offers an intuitive touch-screen interface for simple, efficient operation.

- The advanced system functions help boost processing efficiency while maintaining precise, high-quality grooving.

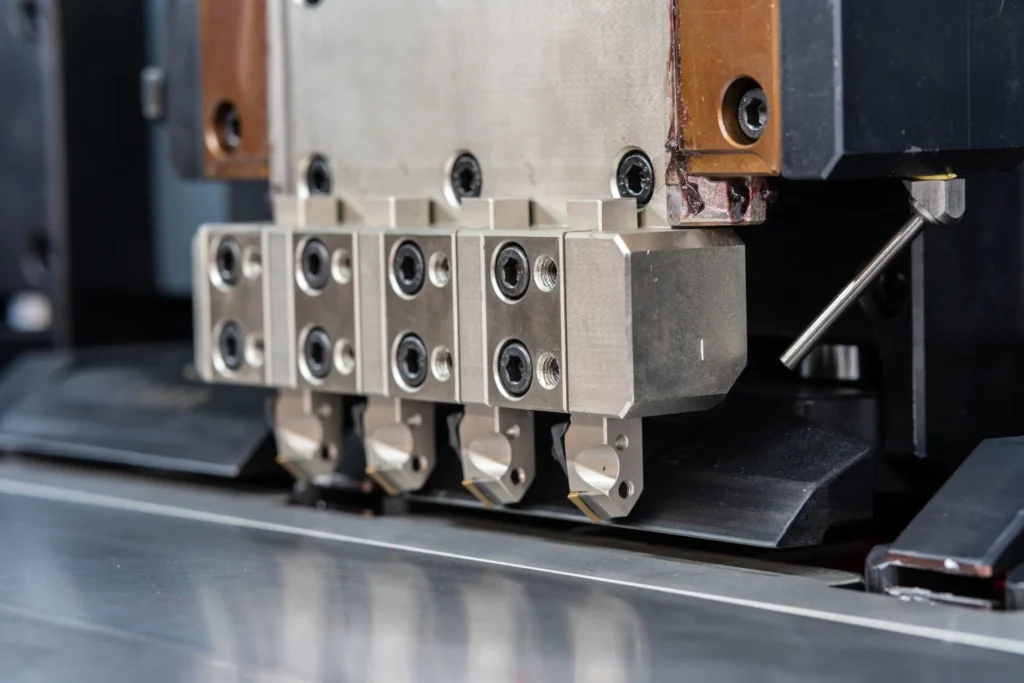

Alloy Blade

- This grooving machine uses a four-blade cutting system, ensuring even grooving with every pass. The blades are made from alloy steel for added strength and longevity.

- Additionally, a dual-nozzle air-blowing system keeps the workspace clear by efficiently removing debris during the cutting process.

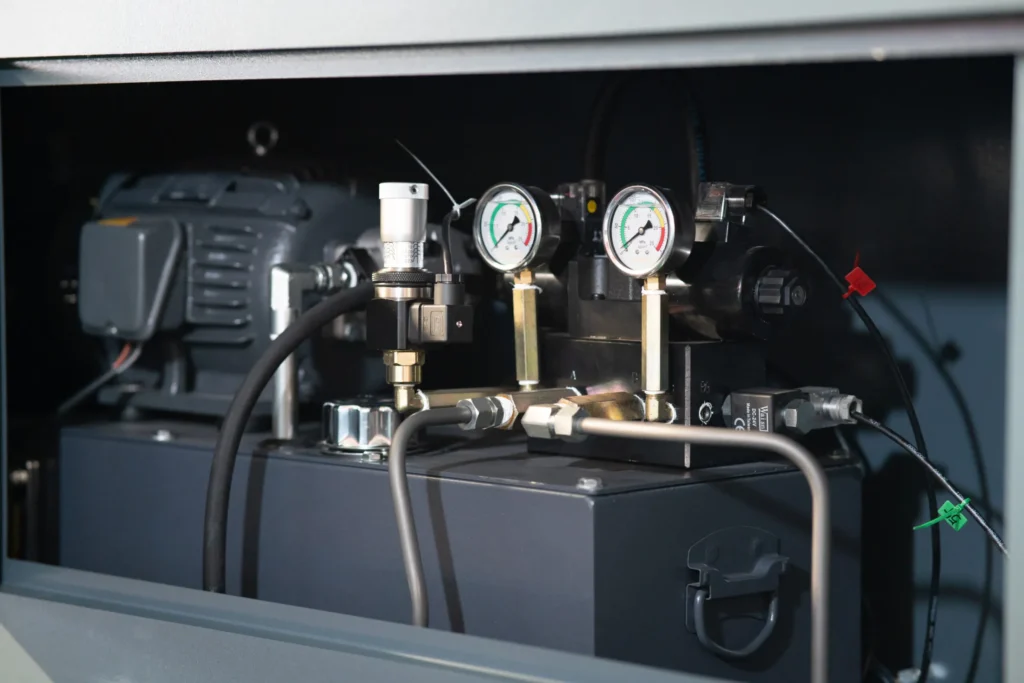

Hydraulic System

- The hydraulic system is powered by Japan’s Yuken technology, known for its reliability and strong performance, ensuring consistent power and durability.

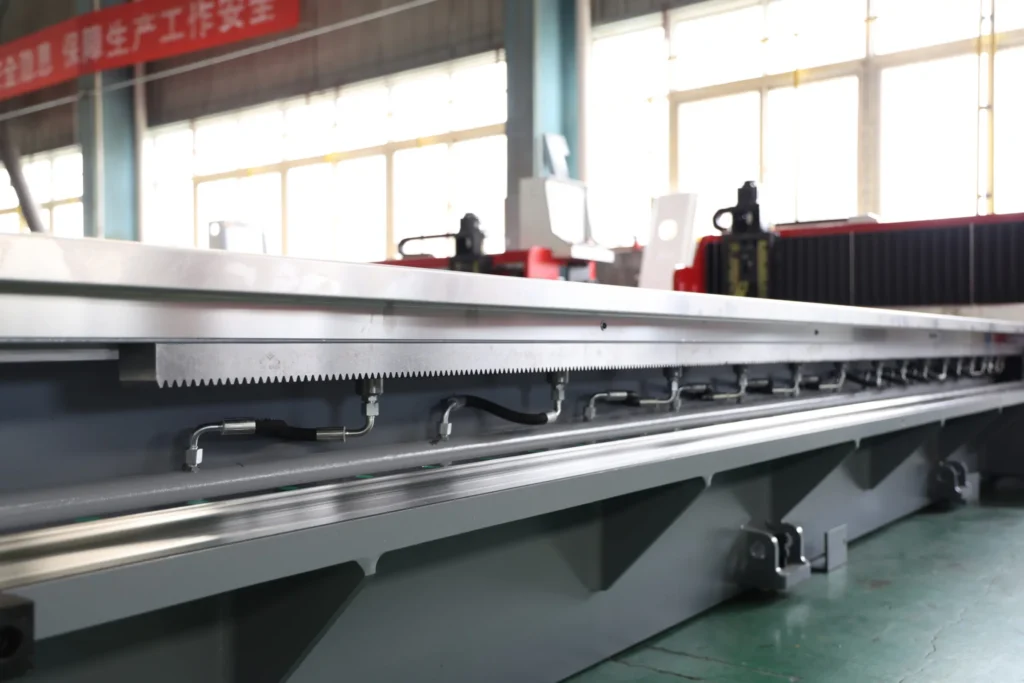

Guide Rail & Rack

- The machine incorporates precision guide rails and racks, enhancing stability and ensuring smooth movement during operation.

- This setup improves the overall accuracy of the grooving process, reducing wear on components and prolonging the machine’s lifespan.

Worktable

- The 60mm low-alloy, high-strength structural steel worktable offers exceptional load-bearing capacity, providing a stable and durable surface for precise grooving.

- Its solid design helps reduce vibrations, ensuring smooth, accurate results every time.

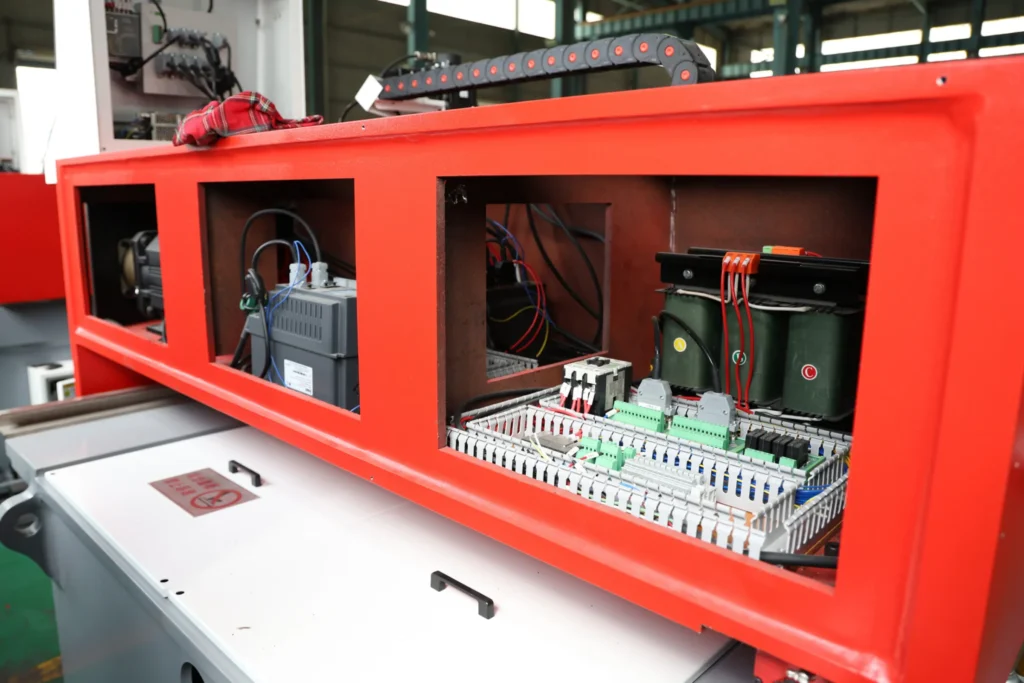

Electrical Cabinet

- The machine is equipped with a well-organized electrical cabinet that houses all key electronic components.

- Designed for easy access and maintenance, it ensures smooth operation and protects the electrical system from dust and external damage.