When it comes to bending sheet metal, choosing between a panel bender and a press brake can be a tough decision. Both machines offer unique advantages, but the right choice for your business depends on factors like production volume, material type, and precision requirements.

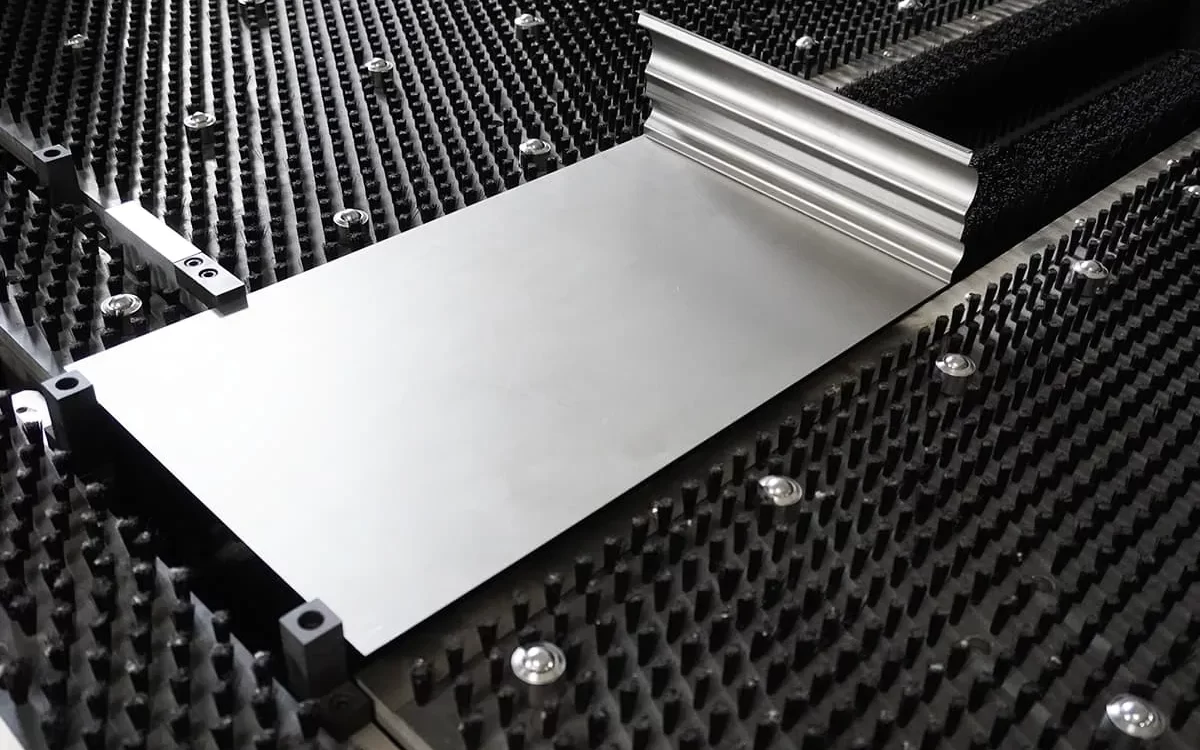

What Is a Panel Bender?

A panel bender is an advanced sheet metal bending machine that automates much of the bending process. It’s designed for high-speed, high-precision production, making it ideal for manufacturers with large-scale operations. Panel benders use a rotating bending blade that moves up and down to form bends in the sheet metal, allowing for automated production with minimal manual intervention.

Panel benders, like the ones offered by Haden, are known for their ability to handle complex bending sequences with incredible speed and accuracy. If you’re in an industry where production efficiency and precision are critical, a panel bender might be the machine you need.

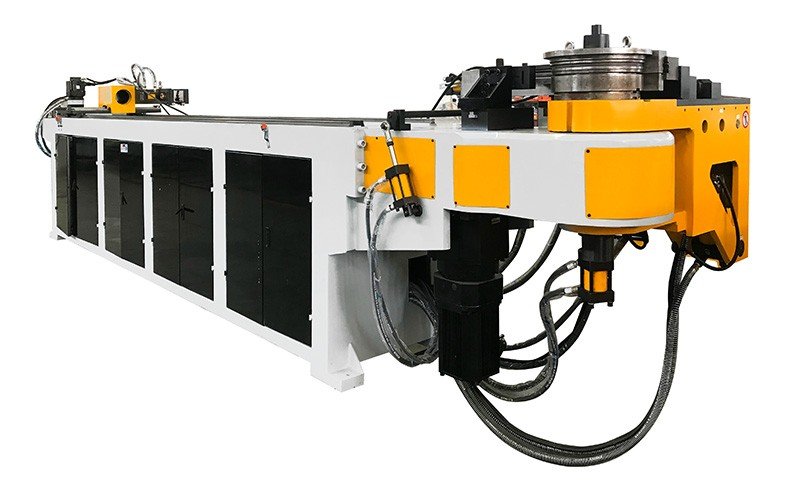

What Is a Press Brake?

A press brake is a more traditional bending machine that uses a punch and die system to bend metal sheets. Press brakes can be manual, hydraulic, or CNC-controlled, offering a range of options depending on the level of automation and precision you need. They’re versatile machines that can handle a wide variety of bends and materials, making them popular in small to mid-sized shops.

At Haden, we offer both hydraulic press brakes and CNC press brakes, which are built for precision, durability, and ease of use. If you need flexibility in your operations and want a machine that can handle different jobs, a press brake might be the right choice.

Key Differences in Production Speed

One of the biggest differences between a panel bender and a press brake is the production speed. Panel benders excel in high-speed production environments because of their automated processes. They can handle multiple bends in a single sequence without needing to reposition the material manually. This makes panel benders ideal for manufacturers who need to produce large quantities of parts quickly.

In contrast, press brakes typically require manual intervention to reposition the material for each bend, which can slow down production. However, for smaller batches or custom jobs, the press brake’s flexibility can be more beneficial.

Precision and Complexity of Bends

If your business requires highly complex bends with tight tolerances, a panel bender might be the better option. Panel benders can perform a variety of intricate bends in a single pass, making them perfect for industries like aerospace, electronics, and automotive, where precision is paramount.

Press brakes, on the other hand, offer flexibility but may not match the precision of a panel bender, especially for complex, multi-step bends. However, CNC press brakes can still achieve a high degree of accuracy, particularly in jobs where precision is needed but not as critical as in large-scale automated production.

Material and Thickness Capabilities

When it comes to material handling, both panel benders and press brakes can work with a wide range of materials, including steel, aluminum, and stainless steel. However, panel benders tend to be better suited for thinner materials, as their automated systems are optimized for high-speed bending of light sheet metal.

Press brakes, especially hydraulic press brakes, are often better equipped to handle thicker materials and more robust bending jobs. This makes them ideal for industries where the metal is heavier, such as in construction or shipbuilding.

Cost Considerations

Cost is always an important factor when choosing between a panel bender and a press brake. Panel benders, due to their advanced automation and speed, generally come with a higher upfront investment. However, if your business focuses on high-volume production, the time savings and efficiency of a panel bender can quickly offset the initial cost.

Press brakes tend to be more affordable, making them a great option for businesses that require versatility and flexibility in their operations. At Haden, we offer both panel benders and press brakes at competitive prices, ensuring you get the best value for your investment.

Which Is Best for Your Business?

The decision between a panel bender and a press brake ultimately depends on your production needs. If you’re a high-volume manufacturer looking for speed and precision, a panel bender may be the better choice. However, if your business values flexibility and cost-effectiveness, a press brake might be more suitable.

At Haden, we specialize in providing high-quality bending machines tailored to your specific needs. Whether you need a panel bender for high-speed production or a CNC press brake for versatile, precise bending, we have the solutions to help your business grow.

Conclusion

Both panel benders and press brakes have their place in modern manufacturing, and understanding the differences between the two can help you make an informed decision. If you’re still unsure which machine is right for your shop, don’t hesitate to reach out to Haden. Our team of experts is ready to guide you toward the best solution for your production needs.