Amada/European Press Brake Punches Made in China: Quality and Competitiveness

Amada and European-style press brake punches manufactured in China have gained significant traction in the global market in recent years. With advanced manufacturing techniques and competitive pricing, Chinese-made punches offer a high-quality alternative to original brands, attracting a growing number of international buyers. In this article, we will explore the key features, advantages, and global competitiveness of Amada/European press brake punches made in China.

Advanced Manufacturing Processes and High-Quality Materials

Chinese manufacturers of press brake punches utilize cutting-edge production techniques to ensure that their punches are on par with those produced by original equipment manufacturers (OEMs). The punches are often crafted from hardened steel or high-strength alloys, providing excellent durability and performance. These materials undergo precision machining, heat treatment, and rigorous testing to meet international standards. The result is a product that offers longevity and precision in sheet metal forming applications.

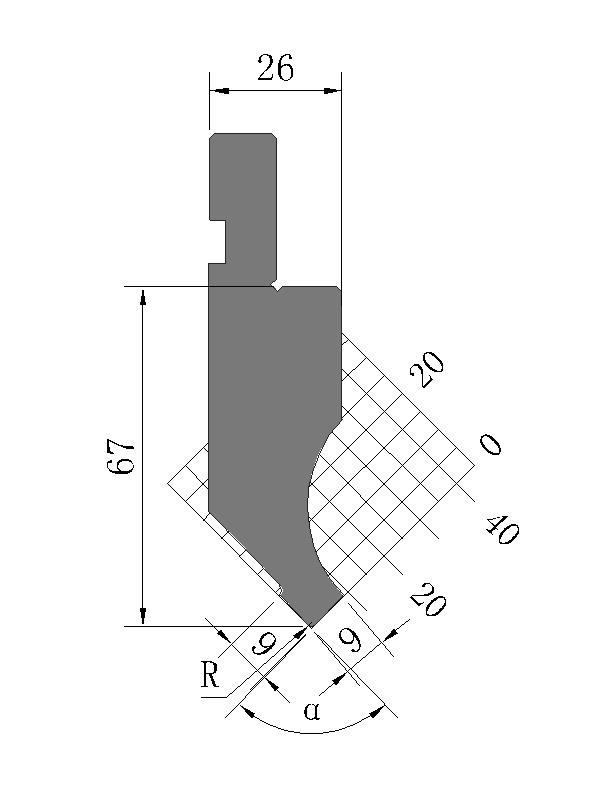

Insert image of precision-machined press brake punches made in China, highlighting the manufacturing process and materials used.

Customization and Compatibility with International Standards

One of the major advantages of Chinese-made press brake punches is their high level of customization. Many manufacturers offer tailored solutions to meet the specific needs of their clients, ensuring that the punches are compatible with a variety of press brake machines, including Amada, Trumpf, and other European models. This versatility is particularly attractive to businesses seeking to optimize their sheet metal fabrication processes without investing heavily in OEM parts.

Insert image of various types of press brake punches compatible with Amada and European models, showcasing their adaptability.

Competitive Pricing Without Compromising Quality

While pricing is a key factor that drives many companies to source from China, it does not come at the expense of quality. Chinese manufacturers have invested heavily in state-of-the-art production facilities, automation, and skilled labor, enabling them to produce high-quality punches at a fraction of the cost of those made in Europe or Japan. This affordability has allowed companies, both large and small, to maintain competitive operational costs while still benefiting from durable and reliable tooling.

Insert image of a production facility in China showcasing modern manufacturing equipment and skilled workers producing high-quality press brake punches.

Global Reach and Rapid Growth

China’s export of press brake punches has expanded rapidly over the past decade. Manufacturers are increasingly focused on meeting the demands of international clients, adhering to ISO standards, and providing quick turnaround times for bulk orders. This global reach, combined with the ability to deliver quality products at competitive prices, has enabled Chinese manufacturers to establish a strong presence in markets such as Europe, North America, and Southeast Asia.

Insert image of press brake punches being prepared for export, symbolizing China’s expanding presence in the global market.

Future Trends in the Press Brake Tooling Industry

As the global sheet metal fabrication industry continues to evolve, Chinese manufacturers are keeping pace with technological advancements, such as automated punch production, enhanced material coatings, and smart tooling solutions. These innovations are expected to further solidify China’s position as a leader in the production of high-quality press brake punches for both Amada and European-style machines.

Insert image of modern press brake tooling technology, representing the future of the industry and Chinese innovations.

In conclusion, Amada/European-style press brake punches made in China offer an excellent balance between quality, customization, and affordability. As Chinese manufacturers continue to improve their production processes and expand their global footprint, they are well-positioned to meet the growing demands of the international market. For businesses seeking reliable and cost-effective tooling solutions, China remains a top choice.