Fiber Laser Cutting Machine

Fiber laser cutting machines have a significant advantage over other cutting tools such as plasma or flame cutters in terms of speed and precision. In the field of metal processing, fiber laser cutting machines play a crucial role due to their advanced capabilities. Key benefits include:

- Speed: Fiber lasers offer much faster cutting speeds compared to plasma or flame cutting methods, improving overall productivity.

- Precision: They provide superior accuracy and detail, resulting in cleaner cuts and tighter tolerances.

- Efficiency: Fiber lasers are highly efficient with minimal material waste and reduced energy consumption.

These advantages make fiber laser cutting machines an essential tool in modern metal fabrication, enhancing both the quality and efficiency of metal processing operations.

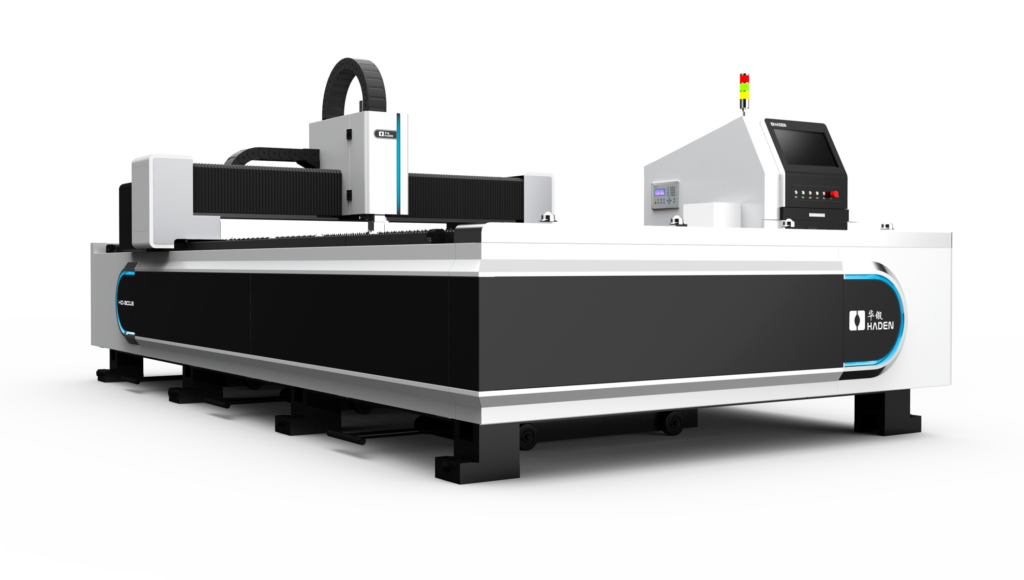

Model: S

- The S Series represents single-platform laser cutting machines designed for flat metal cutting applications.

- It’s ideal for small, startup fabrication shops.

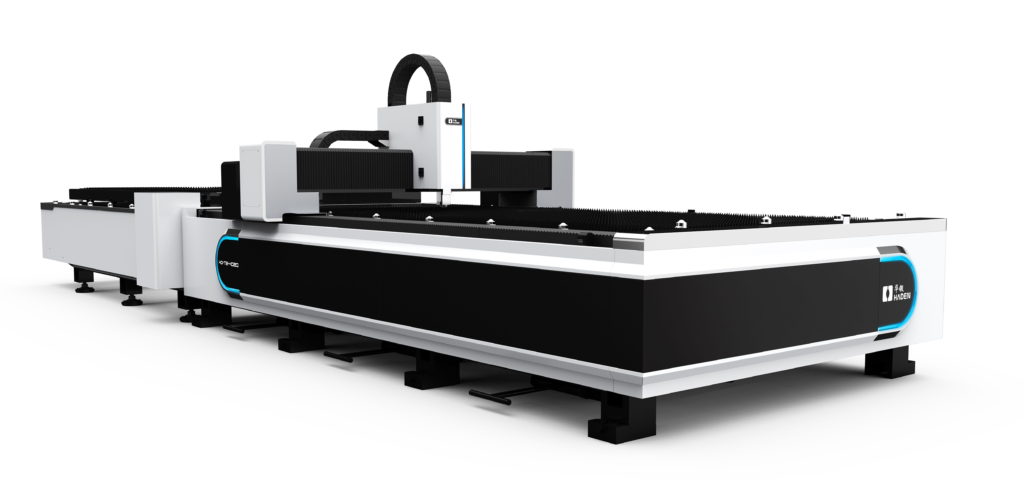

Model: E

The E-series sheet metal fiber laser cutting machine: represents parallel exchange double work platforms, enhancing production efficiency.

Model: C

- The C-series represents Combo sheet & tube laser cutting machines, expanding production capabilities.

- It can cut both metal sheets and metal tubes.

Model: T

The T-series represents professional tube/pipe cutting machines, designed for businesses that require extensive pipe processing.

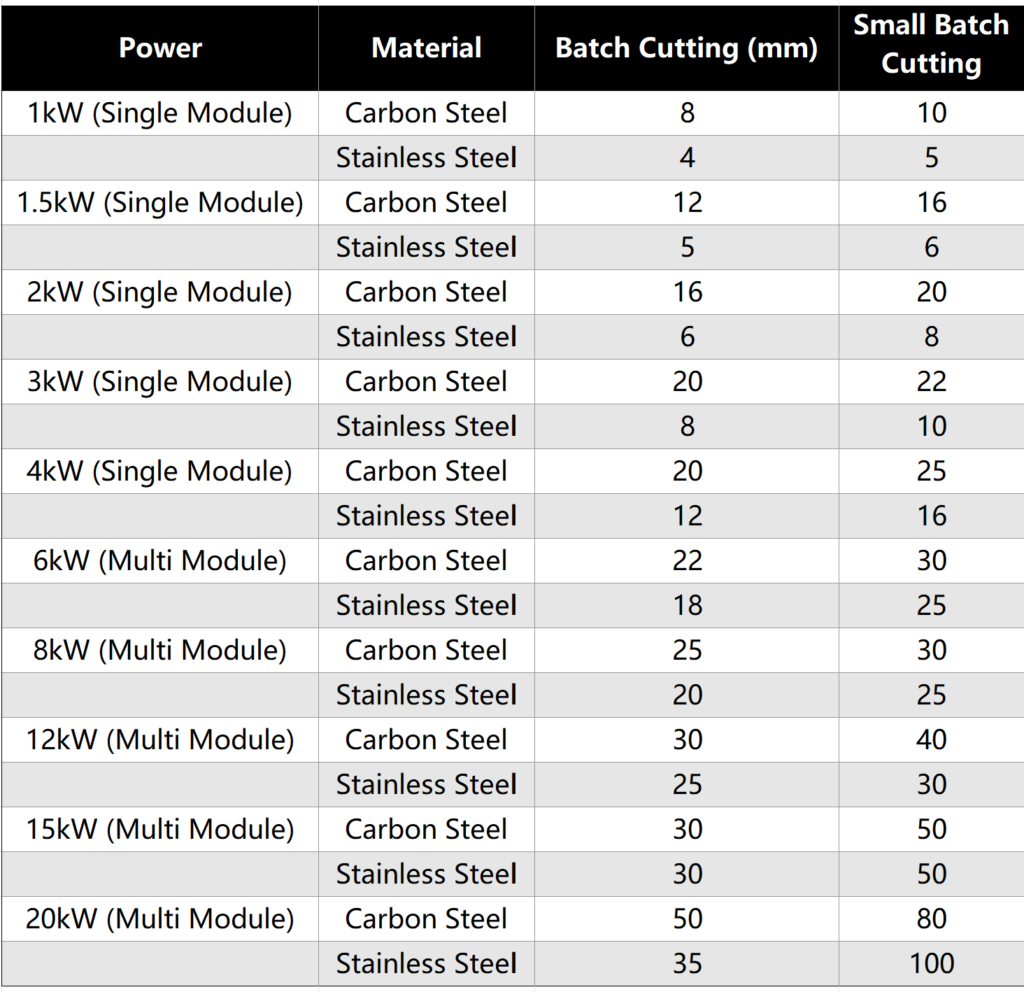

Common specifications:

- Chuck Pipe Diameter: 10-600 mm

- Clamping Length: 6, 12, 18, 24 meters

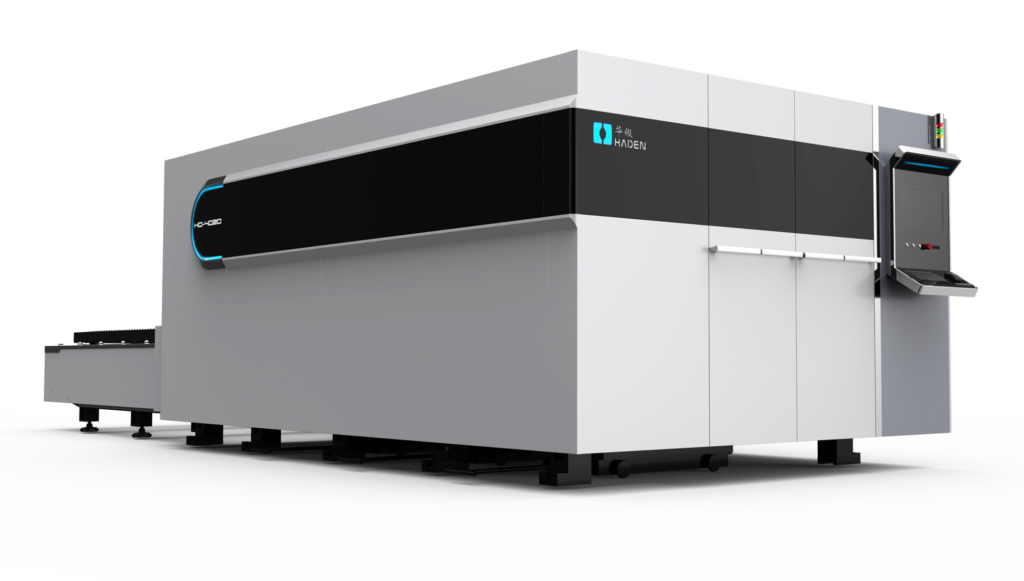

Model: CC

The CC-series stands for Combo with Cover. It is designed to protect operators’ safety by significantly reducing the risk of laser cutting hazards to the human body.

Model: EF

- The EF series represents exchange worktables with full cover sheet metal.

- It greatly enhances the environmental quality of the production workshop while ensuring safety protection.

- Suitable for high-end dust-free workshops and is typically used in conjunction with a dust extraction system.

Tailor Your Solution to Your Business Needs

Buy Local

Premium Service from Local Experts-

Import

-

Installation

-

Training

Import Directly

Factory-Direct Pricing for Experts-

3-Year Guarantee

-

Online Support

-

Custom Solutions

Partner Up

Join Our Agent Network-

Client Inquiries Provided

-

On-Site Technical Training

-

Flexible Payment Terms

Contact Our Experts

For more specific cutting material parameters, detailed cutting data reference charts, operating costs, consumable costs, customization needs, and more.

Why choose us?

1. Unmatched After-Sales Support

2. World-Class Talent & Design Expertise

3. Rigorous Production & Quality Standards

4. Dedicated Media Team in the Works

Warranty

Cybcut Laser Cutting System

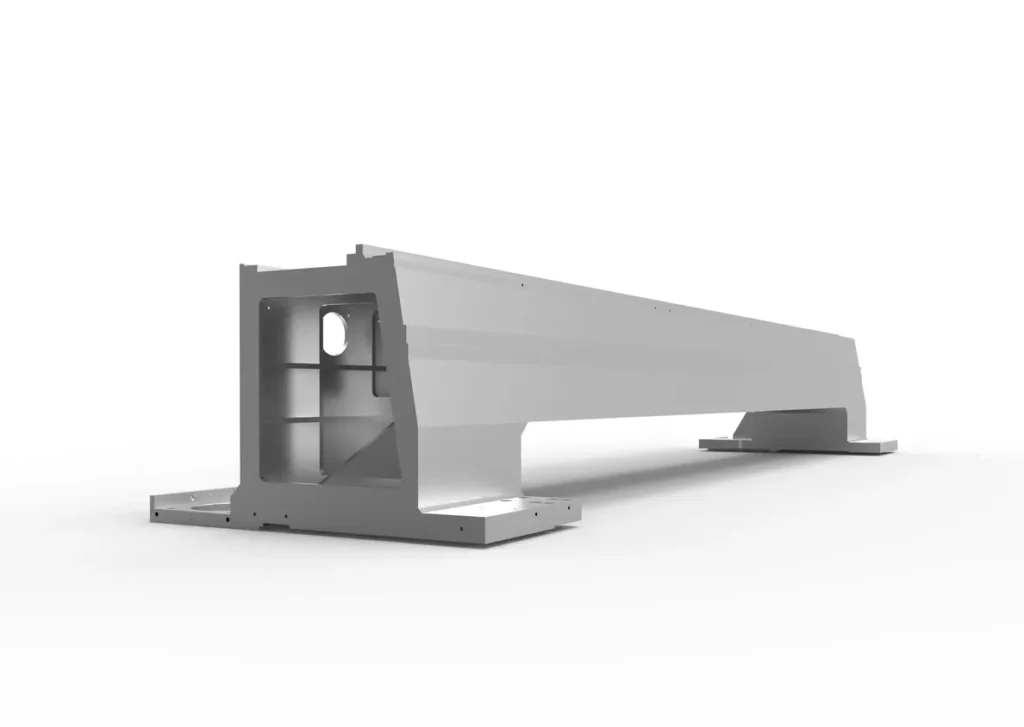

Machine Bed

Heavy-duty structure bed, welded from 10mm steel plates, ensuring stability.

The entire machine undergoes high-temperature quenching and heat treatment, guaranteeing no deformation for 20 years.

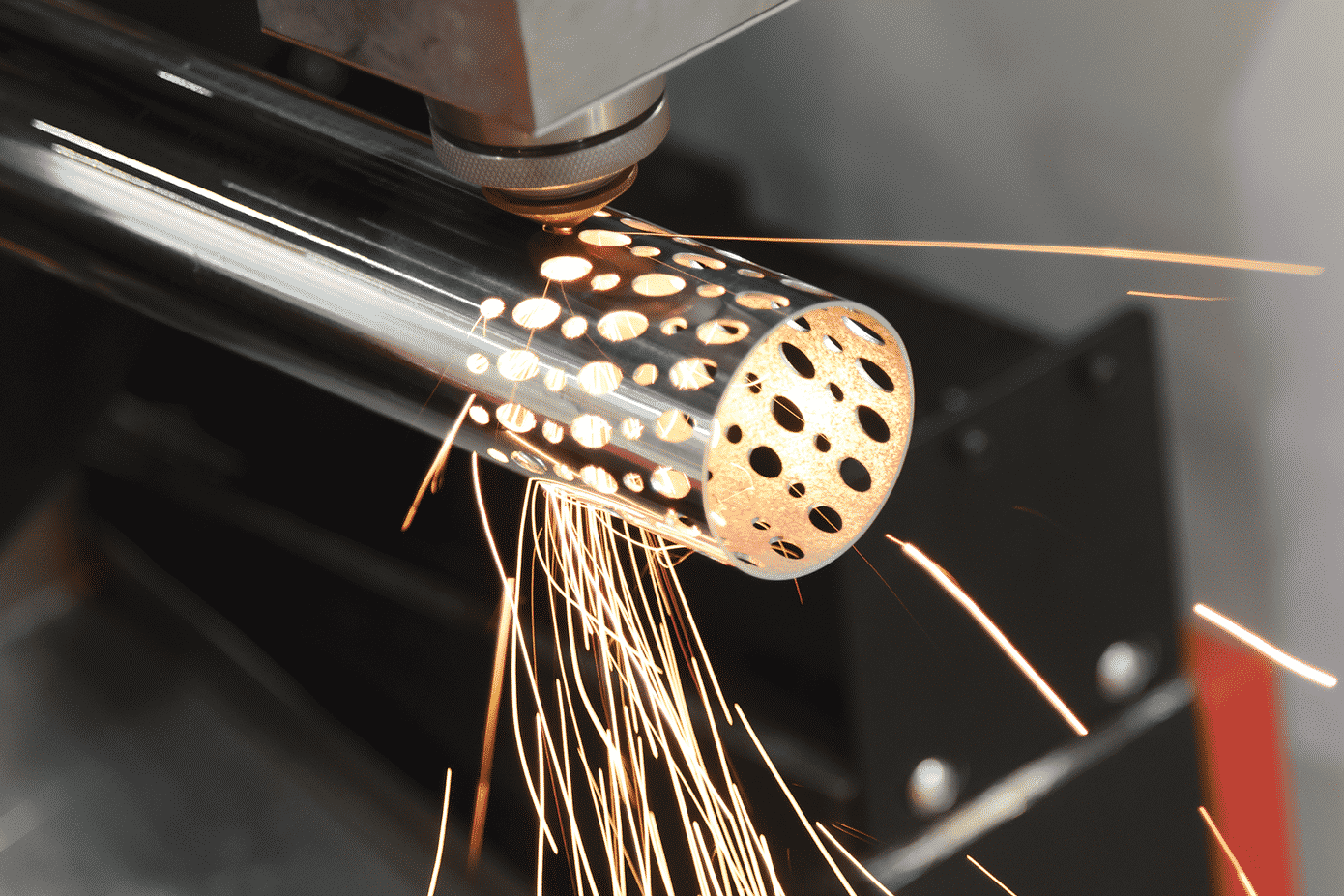

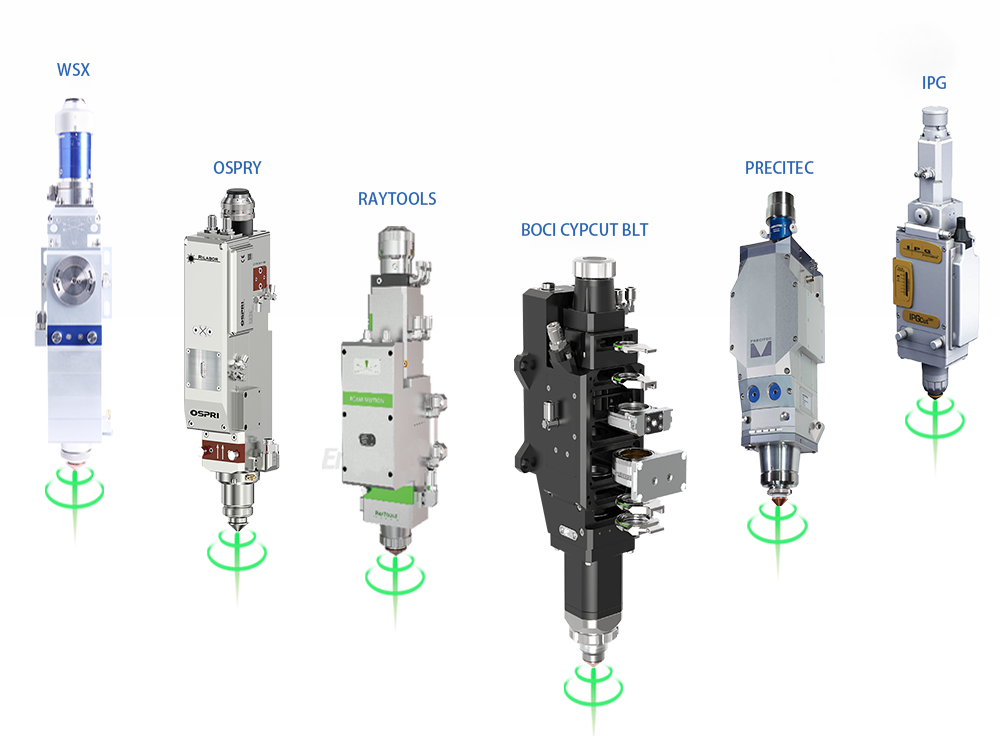

Cutting Head

- Communication and auto focus control based on EtherCAT.

- 4-Color LED lamps to monitor status.

- Optimized optical configuration and smooth gas circuit.

- D30mm combo lens to support laser up to 3.3KW.

- Top cover glass is used to further protect collimation lens.

- Drawer type cover glass holder to facilitate replacement.

- Standard QBH/QD (LLK-D) interfaces to work with different fiber lasers.

Fiber Laser Source

- We adopt MAX or Raytool lasers as standard configurations. In terms of mid-to-low power, their advantages are significantly greater than those of the German IPG fiber lasers.

- The standard configuration includes the Wuhan Hanli water chiller.

Haven't found the solution yet?

Cast Aluminum Beam

In order to increase the acceleration of fiber laser cutting, we improved the cast iron crossbeam by adopting a cast aluminum one. While ensuring rigidity, the crossbeam is lighter.

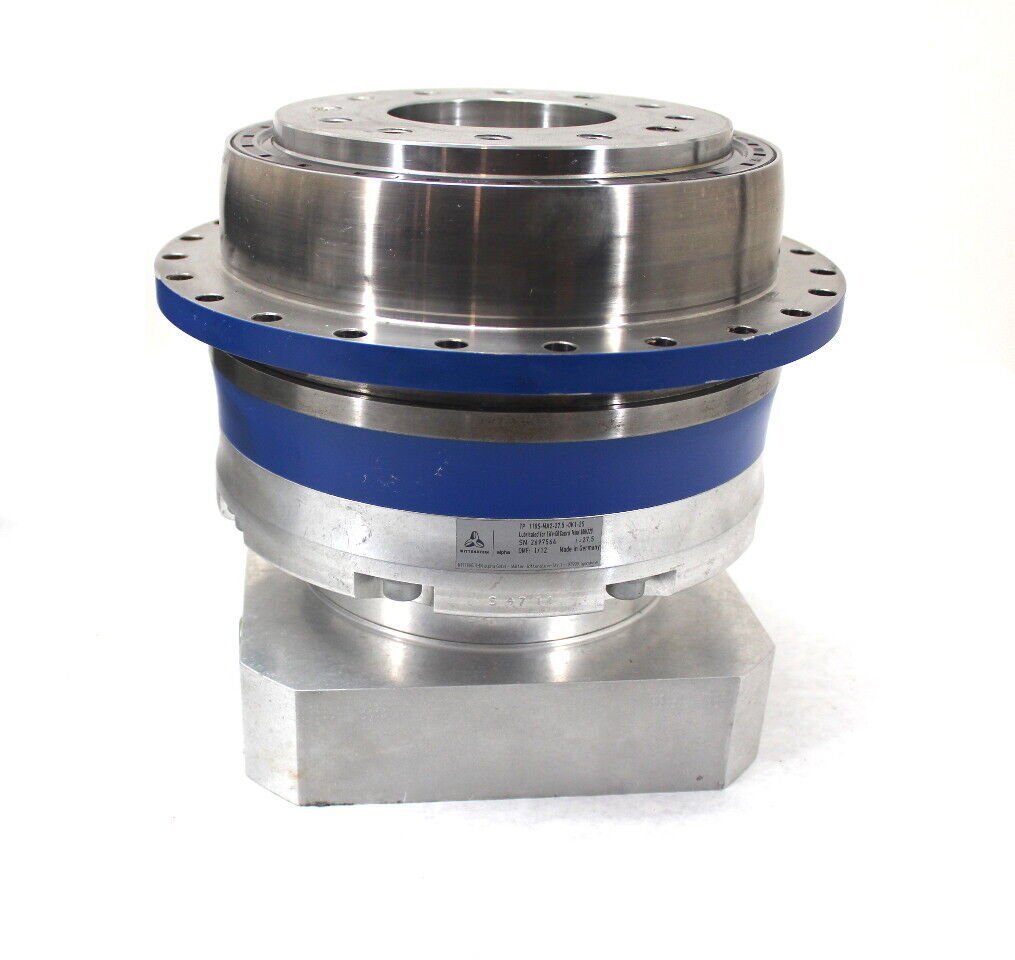

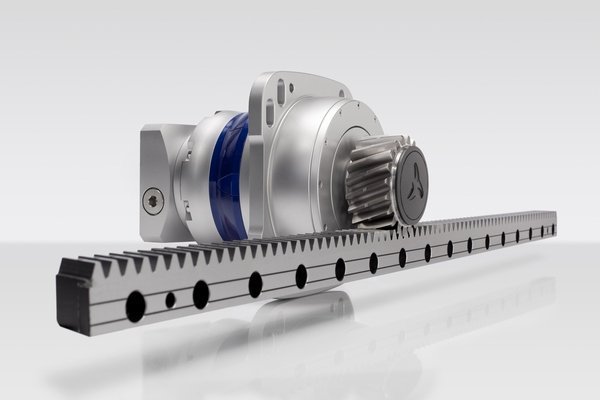

Master reducer

France Motoreducer

Optional: Japan Smagic

Optional: Germany Alpha

For ultimate stability

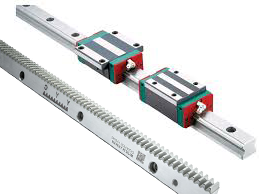

Hiwin Racks & Guide Rails

Optional:Japan SMAGIC

Optional:Germany Rexroth

The Ultimate Acceleration

China Taiwan Delta

Optional:Japan Yasakawa

Other Standard Configuration