What is Tube Laser Cutting?

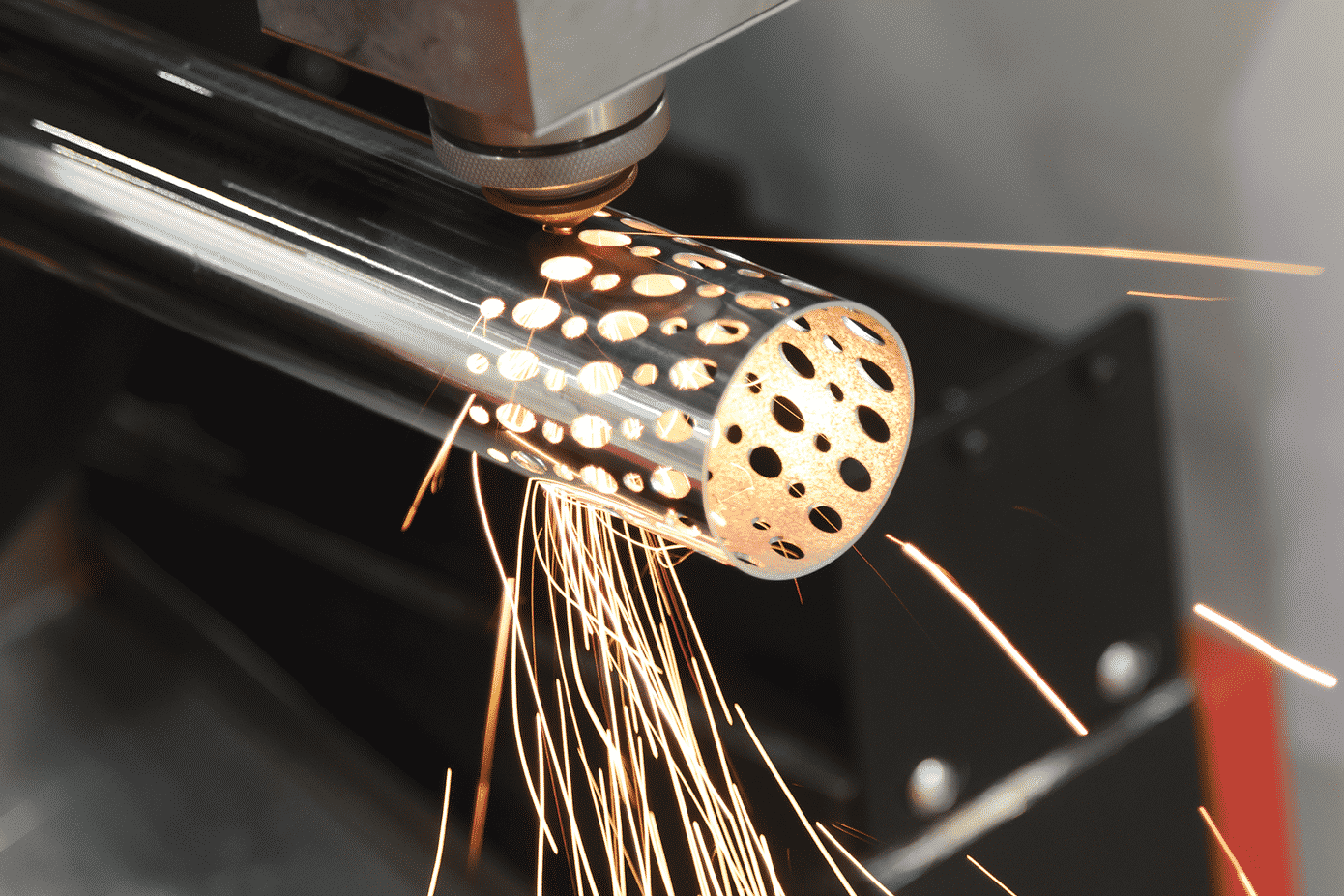

Tube laser cutting is a highly precise and efficient method for cutting metal tubes and pipes using a laser beam. Unlike traditional cutting methods, which can be time-consuming and less accurate, tube laser cutting offers enhanced flexibility and precision, making it ideal for industries that require complex and detailed metalwork.

How Does Tube Laser Cutting Work?

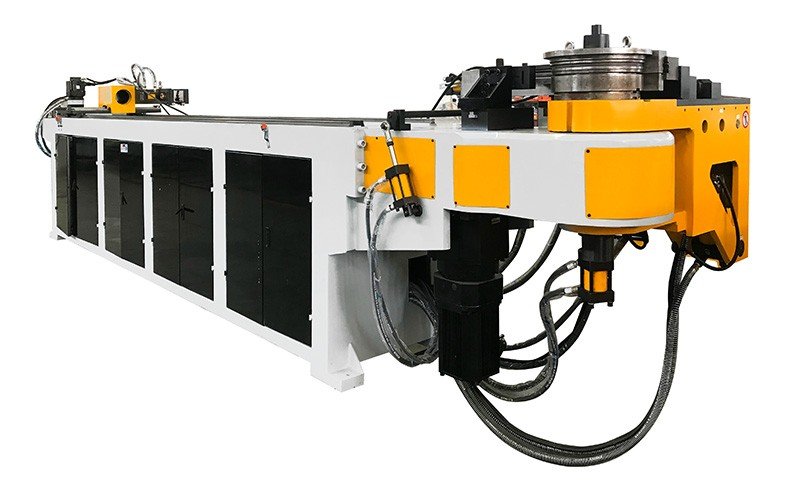

Tube laser cutting utilizes a fiber laser to create a focused beam that cuts through metal tubes with exceptional accuracy. The process begins by loading the tube into a laser cutting machine, where it is securely held in place. The laser beam is then directed along the tube’s surface to cut it into the desired shape or length.

Haden specializes in advanced tube laser cutting machines that ensure precise cuts and high-quality finishes for a variety of applications.

Benefits of Tube Laser Cutting

- High Precision: Tube laser cutting delivers superior accuracy compared to conventional methods. This precision is crucial for producing intricate designs and meeting tight tolerances in metal fabrication.

- Versatility: The technology can cut various materials, including stainless steel, aluminum, and carbon steel, and handle different tube sizes and shapes. This makes it a versatile option for many industries.

- Reduced Waste: The accuracy of laser cutting minimizes material wastage. By precisely cutting only the required sections of the tube, you can reduce costs associated with scrap metal.

- Speed and Efficiency: Tube laser cutting machines operate quickly, allowing for rapid production of complex parts. This efficiency can lead to faster turnaround times and higher productivity.

- Minimal Secondary Processing: The clean cuts produced by laser cutting often require little to no additional finishing work, saving time and labor costs in post-processing.

Applications of Tube Laser Cutting

Tube laser cutting is used across various industries, including:

- Automotive: For cutting and shaping exhaust systems, roll cages, and other metal components with intricate designs.

- Aerospace: In producing precision parts for aircraft and spacecraft, where accuracy is critical.

- Furniture: For creating stylish and functional metal furniture pieces with unique designs.

- Construction: In fabricating structural components and metal supports for buildings and infrastructure.

Comparing Tube Laser Cutting to Traditional Cutting Methods

When compared to traditional cutting methods, such as plasma or saw cutting, tube laser cutting offers several advantages:

- Accuracy: Laser cutting provides much finer precision and cleaner edges than traditional methods.

- Flexibility: It can handle a wider range of materials and tube geometries.

- Speed: The cutting process is generally faster, improving overall production efficiency.

Maintenance and Care for Tube Laser Cutting Machines

To ensure your tube laser cutting machine operates optimally, regular maintenance is essential:

- Clean the Lenses: Regularly clean the laser lens to prevent buildup that can affect cutting quality.

- Inspect Nozzles: Check and replace nozzles as needed to maintain consistent performance.

- Maintain Cooling Systems: Ensure that the cooling system is functioning correctly to prevent overheating.

- Lubricate Moving Parts: Regularly lubricate the machine’s moving components to prevent wear and ensure smooth operation.

- Schedule Professional Service: Arrange for periodic professional inspections to catch any potential issues before they become serious problems.

Why Choose Haden for Your Tube Laser Cutting Needs?

At Haden, we provide state-of-the-art tube laser cutting machines designed for high performance and reliability. Our machines are equipped with advanced features to handle a range of materials and cutting requirements, ensuring you get the best results for your projects.

Conclusion

Tube laser cutting offers a precise, efficient, and versatile solution for a variety of metal cutting needs. With its numerous benefits and applications, it stands out as a superior choice for modern metal fabrication. For businesses seeking reliable and high-quality tube laser cutting solutions, Haden is here to provide the cutting-edge technology and support you need to achieve your goals.